Development & Testing

What goes into a Pedal Easy design?

In developing and refining our e-bikes we make use of bench-type testing to supplement field-testing. We have been doing this on an ongoing basis for over 10 years now. Such testing is used for research & development in many other industries as well. Its value or even its significance may not be obvious to everyone, but basically, relative to field testing, it allows control of extraneous variables so we can get to the root of factors causing good or bad performance. Bench testing points the way to product improvement, often to an extent not possible with field testing.

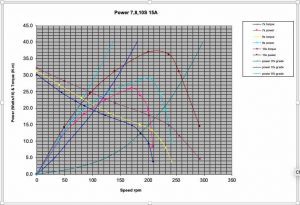

Most of the components on our e-bikes (motors, controllers, throttles, batteries) were selected from candidates screened and evaluated by such tests. We have test equipment to achieve many ends. A variable-load simulator allows us to simulate a wide range of uphill grades and measure the response of the power-assist system. A bench test for discharging batteries through resistors, while monitoring voltage, current, power & temperature allows us to evaluate and compare battery discharge characteristics & capacity under load. A hub-motor dynamometer (Figure 1), that measures motor output torque as a function of speed and electrical power input has helped us establish motor, controller & battery performance characteristics (Figure 2), and optimal voltage levels and current limits.

Field-testing supplements bench-testing, refines our product, and ensures it is as functionally perfect and as robust as we can make it. We use beta testing, post-service inspections and customer feedback. Most importantly, we ride these bikes a lot ourselves, and are continually monitoring for improvements. From time-to time we even involve our customers in our R&D. For example, a client with a long city commute with dozens of stoplights requiring frequent heavy braking helped us evaluate and select brake pad materials; and another customer with a particularly aggressive rural commute helped us refine optimal parameters for the power controller (we instrumented his bike with recorders of various types and monitored and “tweaked” it for several years).

|

|

| Dynamometer for hub-motor tests | Typical output power & torque at 3 voltages |